This means carving milling machine. It can even carve mill. On the basis of increasing the spindle, the Yiming engraving machine adopts what kind of motor power, the bearing capacity of the bed, while maintaining the high speed of the spindle, more importantly, high precision. Large scale engraving machine is also developing at a high speed, that is, high-speed machine, which has strong cutting ability high processing accuracy, but it can also directly process materials with hardness higher than HRC60 for secondary molding.

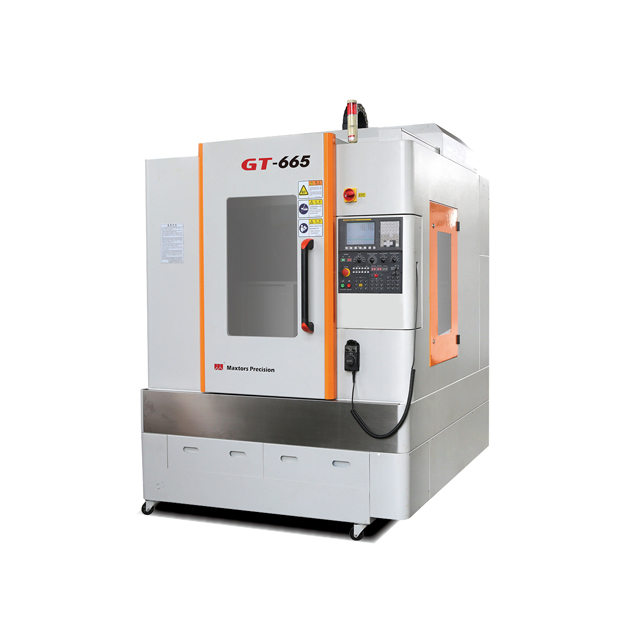

It is generally considered that the tool is a small, high-power, high-speed spindle motor Yiming CNC engraving milling machine. The advantage of engraving machine in carving, if the hardness of processing material is relatively large, it will also appear powerless. The emergence of milling machine can be said to fill the gap between the two. Engraving milling machine is a kind of high-efficiency high-precision CNC machine tool. The concept of engraving milling machine is put forward realized. The utility model has a wide range of applications, is widely used in the rough machining of precision mold, copper electrode of mold, batch processing of aluminum products, shoe mold manufacturing, cutting tool processing watch industry. Engraving milling machine plays an important role in machine tool processing industry, is an indispensable part of industrial automation.

matters needing attention

1. The Gong of milling machine must rotate more than 1.01 million. Many friends of computer gong have never used milling machine. The idea of processing gongs with computers is wrong. For gongs must be forced to rotate speed, too fast, easy to burn out, so milling machine is also a reason, so milling machine has a set of fast, slow gear. This is because the computer cheongsam milling machine can only have higher torque at low speed. The motorized spindle used in engraving milling machine must rotate at about 10000 rpm can output large torque. If you use a computer gong, you can also drive the spindle speed of about 2000. When the machine is rough, it is easy to discard the motorized spindle.

2. When the rotating speed is too low, the sound of the motorized spindle sinks, the drum force occurs in the process of processing, sometimes the spindle cannot rotate, the inverter alarms that it is overloaded. Serious damage can result in spindle waste.

3. Flushing oil is also required during processing. When the Gong is rough, there is no need for flushing oil.